Excavator Idler Wheel & Track Rollers: How They Impact Performance & Longevity

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

If there’s one thing we’ve learned in our 40+ years of supporting contractors across mining, construction, and infrastructure, it is that excavator undercarriages rarely need a full replacement. Undercarriage is a complex system composed of different components. Usually, timely maintenance, repair, and replacement of these components is enough to keep the system functioning smoothly. Among all undercarriage components, the excavator idler wheel and track rollers play a decisive role in machine stability, precision, and long-term operating cost.

Several times, our clients reach out when the track keeps drifting or the machine vibrates more than it should. These aren’t random issues. They’re warning signs. And over the years, we’ve seen exactly how these become bigger failures that cost more time, fuel, and money.

So, here is a guide to help operators understand why these failures happen and how to stay ahead of them.

The Role of Excavator Idlers and Rollers in an Undercarriage

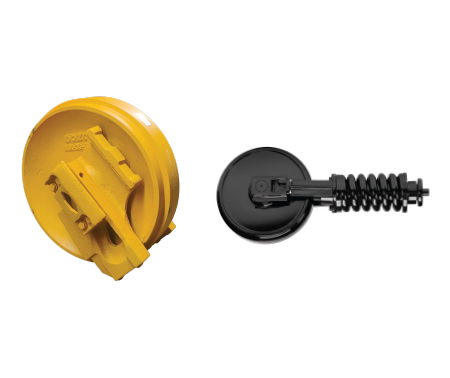

Each part of a machine’s undercarriage plays a different role in the system. The idler wheel of an excavator, for instance, maintains track alignment, absorbs forward chain movement, and supports proper tensioning.

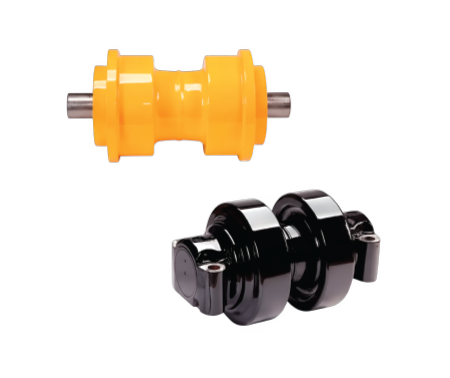

Track rollers, especially the bottom ones, support the weight of the entire machine, not just the undercarriage. Depending on the excavator model you own, the number of track rollers might vary.

Since these components are critical, when either of them wears prematurely, the entire undercarriage begins to lose efficiency, leading to:

- More fuel consumption

- Higher load on the drive motor

- Poor track alignment

- Faster deterioration of links, bushings, and sprockets

Common Wear Patterns We Have Frequently Observed in the Field

While the wear might occur due to various reasons, we have seen these common wear patterns across multiple working conditions:

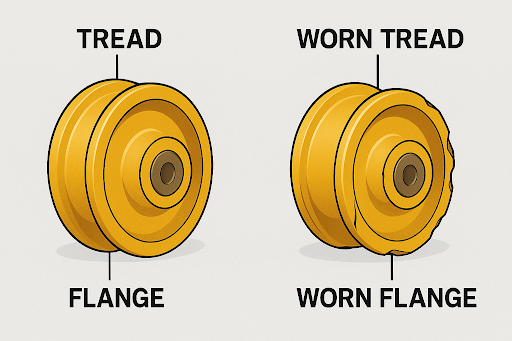

1. Excavator Idler Wheel Wear

- The tread of an idler wears down as there is constant rolling contact between the idler tread and the link rail, especially in abrasive soil.

- The Flange side also wears wear due to misalignment or side-loading forces the chain to rub against the flange.

- Top flange wear usually occurs due to excessive track tension pushing the chain upward onto the flange surface.

- Tread cracks are a result of repeated high-impact loads on rocky or uneven terrain stressing the tread surface.

2. Track Roller Wear

- Under heavy operating loads, rollers experience higher contact pressure on the link rail, accelerating tread wear.

- When working in mud, packed soil can stop roller rotation, grinding one area into a flat patch.

- Loose tension or misalignment causes the flange to move side-by-side which causes wear.

Root Causes Behind These Issues

While these wear patterns appear on the components, the underlying reasons usually trace back to a few consistent operational factors, such as:

1. Improper Track Tension

Depending on the soil condition, you need to check the track tension needs daily or weekly. Since many excavators work in remote locations, in most cases, the operator or on-site maintenance person handles it. However, if it is not done carefully, it can lead to several issues, such as:

- Over-tightened tracks increase heat, friction, and seal stress.

- Loose tracks cause chain whip, flange wear, and bushing climb.

2. Soil Packing

The soil condition is one of the major reasons for undercarriage part wear. Mud, clay, or aggregates often get trapped between rollers and links, and the components can’t rotate smoothly.

This leads to:

- uneven wear

- bearing failure

- flat spots on rollers

3. Misalignment of Undercarriage Components

In many cases, premature wear can be traced back to:

- bent track frames

- worn mounting bearing surfaces

- misaligned idler yokes

- sprocket tilt or lateral offset

Best Practices We Recommend to Contractors and Fleet Owners

If you want to avoid unplanned breakdowns and increase the longevity and performance of your machine, here are a few practices that you should follow:

Daily Walk-Around Inspections

There is no alternative to daily walk-around inspection. It might seem tedious, but that’s how you identify issues early. Monitoring for oil leaks, abnormal roller movement, unusual noise, or excessive heat greatly reduces the risk of sudden failure.

Regular Undercarriage Cleaning

Since an undercarriage is constantly in touch with the surface, it needs to be cleaned. Cleaning the packed soil helps prevent grinding action between components and ensures rollers rotate freely.

Routine Measurement of Wear

Even with the best practice, undercarriage parts like the excavator idler wheel and roller will wear out. So, the best option is to keep track of the wear. Using calipers or ultrasonic gauges to track:

- roller tread diameter

- idler flange wear

- link height

- bushing wear diameter

- provides a reliable projection of service life.

How DOZCO Components Improve Performance and Reduce Lifecycle Costs

DOZCO has been manufacturing undercarriage components for OEMs like Caterpillar, Komatsu, Kobelco, etc. Our idlers and rollers are manufactured with:

- high-performance steel

- precision heat treatment

- hardened running surfaces

- engineered seals and lubricants

Wrapping Up

Machines don’t fail suddenly. There are signs. Excavator idler wheelers and rollers are important parts of an undercarriage system. When these elements are functioning properly, the machine stays stable, and operators don’t experience unusual vibration. And you can prevent premature idler and roller wear with proper maintenance, operating habits, and component selection alignment. By adopting proper operating practices and choosing parts engineered for durability, contractors can significantly extend machine life and reduce downtime.

FAQs

What is an idler roller?

An idler roller is a non-powered undercarriage component that guides the track chain, maintains alignment, and supports smooth track movement.

What is the function of the idler on an excavator?

The idler on an excavator maintains proper track tension, keeps the chain aligned, reduces vibration, and ensures the track rotates smoothly around the undercarriage.

What is the difference between a roller and an idler?

An idler guides the track and sets tension, while a roller (bottom or carrier) supports machine weight, absorbs ground impact, and helps the track run smoothly along the frame.

How can I identify early signs of idler or roller wear?

Common signs include unusual vibration, track drifting, noise during travel, visible flange wear, or heat around rollers.

What causes premature wear in idler wheels?

Typically, abrasive soil, misalignment, excessive track tension, or high-impact working conditions.