A Complete Guide to Excavator Idler Wheel: Function, Types, and Benefits

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

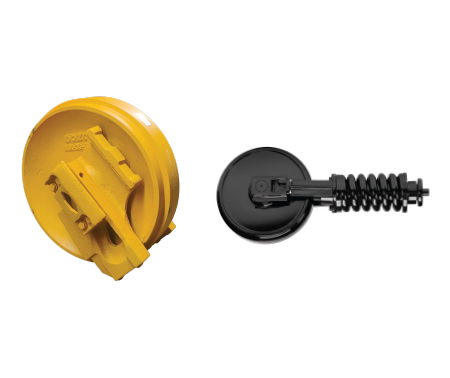

In the undercarriage of an excavator, the idler wheel plays an important role. While it may not drive the track like the sprocket or carry full machine weight like the rollers, the excavator idler wheel guides the track chain, maintains correct tension, and absorbs operational shocks. All these are crucial when you are working in a demanding job that requires precision and stability.

Whether you’re an equipment operator, fleet manager, or service technician, understanding the idler’s function is essential to help you avoid downtime, reduce and improve the lifespan of your excavator undercarriage.

In this article, we are sharing a comprehensive guide on the excavator idler wheel:

Understanding the Excavator Idler Wheel & Its Function

If you are familiar with tracked excavators, you might have seen the front end of the track frame or sometimes the rear houses a large wheel. This is known as the idler. Let’s take a look at its functions:

1. Redirecting the Track Chain

The idler wheel turns the track chain in the right direction. When the chain finishes moving around the sprocket, it reaches the idler, wraps around it, and then continues underneath the machine.

2. Keeping the Track Aligned and Properly Tensioned

For a tracked excavator to move smoothly, the track chain should have the right tension. If the chain is too loose, the track can sway, derail, or cause uneven roller contact. If too tight, components heat up, friction rises, and undercarriage wear accelerates. The idler wheel works with a tensioning system to maintain the correct amount of slack in the chain.

3. Absorbing Shock Loads During Operation

Since tracked excavators move through rocks, uneven sloper, mud, sand or clay, the idler takes the first impact on the front of the track. Its sliding movement along with the recoil or spring-loaded tension unit, absorbs these loads before they reach more delicate components like rollers, pins, and bushings. This is essential to keep the machine stable and also protect other undercarriage parts.

Different Types of Idler Wheels

Excavator idler wheel comes in different types based on the application and undercarriage size, including:

1. Standard Idler Wheel

Standard idler wheels are used primarily on small and mid-sized excavators. DOZCO’s idler wheels usually have hardened outer shells, bronze bushings, and floating seals. These components resist wear and also make sure the idler moves smoothly.

These are suitable for

- General excavation,

- Construction, and

- Utility work.

2. Heavy-Duty Idler Assembly

For more heavy duty tasks like mining, large-scale earthmoving, or aggressive terrain, operators need idlers that are more robust. Heavy-duty assemblies are designed with:

- Reinforced brackets

- Heat-treated, forged steel components

- Thicker shells for impact resistance

- Superior sealing for abrasive environments

3. Front Idler / Tail Roller Variants

Depending on the excavator model, idlers can be positioned either at the front or the rear. Both types guide the track and support tension.

Benefits of a High-Quality, Well-Maintained Idler Wheel

Choosing the right type and high-quality excavator idler wheel comes with several advantages, such as:

1. Better Machine Stability

If a heavy-duty machine like an excavator that weighs tons loses its balance, the entire workplace might turn into a complete disaster. However, when you choose a properly aligned idler, it:

- Reduces sideways movement of the track,

- Improves steering control, and

- Reduces vibration.

This makes the machine more stable when climbing slopes, digging on uneven surfaces, or traveling long distances.

2. Longer Undercarriage Life

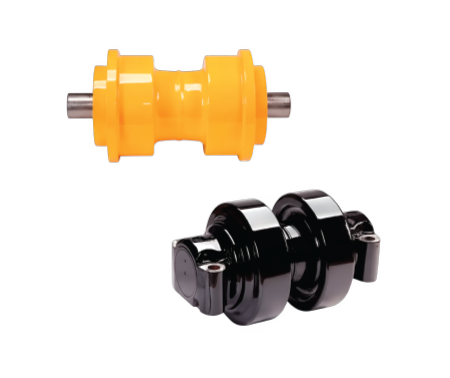

Replacing undercarriage parts can be quite expensive. High-quality idler wheels absorb impact loads and guide the chain smoothly, which reduces wear on other parts, including:

- Track links,

- Bushings,

- Sprockets,

- Rollers, and

- Rail surfaces.

3. Reduced Maintenance and Downtime

When you have a strict deadline, sudden downtime slows down projects. When the idler is maintained properly, the machine runs longer without unexpected failures, helping operators avoid costly downtime and unplanned repairs.

4. Better Performance on Rough Terrain

Excavator idler wheels make sure the machine maintains traction and balance on rocky, muddy, or abrasive ground. This means smoother travel, faster digging cycles, and safer machine handling.

Maintenance Tips for Excavator Idler Wheels

From our above discussion, it is pretty clear that idler wheels play an important role in the overall performance of an excavator. So, here are a few maintenance tips to keep the undercarriage part running smoothly:

1. Daily Visual Inspection

Regular inspections make sure you identify the signs early before they escalate. When checking our machine, look into these:

- Oil leaks around the idler seals

- Cracks or dents on the outer shell

- Loose or missing bolts

- Abnormal noise or grinding

2. Check Bracket Alignment and Mounting

The idler might bend or become loose when you use it for a long time. However, this causes the track to drift off center, which accelerates wear on the idler flange, link rails, and rollers. So, always make sure the idler is properly aligned to prevent the track from becoming “snaky” and keeps the chain moving smoothly during operation.

3. Inspect Seal and Bushing Condition

Excavators work in mud, sand, and other harsh grounds. This increases the chance of contamination. Floating seals and bronze bushings usually reduce friction and keep contaminants out. But if the seal fails, internal components lose lubrication quickly and wear at an accelerated rate. So, replace seals immediately if you see any sign of leakage.

4. Monitor Track Tension and Idler Travel

The idler must move freely with the recoil or spring mechanism to absorb shock loads.

If mud, stones, or ice pack tightly around the idler shell or mounting area, its sliding motion becomes restricted. This can transfer impact forces directly into the frame.

5. Clear Debris Regularly

This goes without saying, but you should always clean the excavator undercarriage thoroughly after use. Remove mud, clay, rocks, and debris from around the idler to prevent the track sag from getting distorted or damaged.

Final Thoughts

The undercarriage of an excavator is made of different components. Each of these parts has a strong significance. The excavator idler wheel is responsible for redirecting the track chain, maintaining proper tension, supporting alignment, and absorbing operational impact. At DOZCO, we manufacture heat-treated idler assemblies that enable machines to achieve better stability, smoother performance, and significantly longer undercarriage life.

FAQs

What should I do if my excavator’s track keeps drifting to one side while traveling?

This usually points to idler misalignment or worn mounting brackets. When the idler isn’t centered, the track pulls to one side, causing uneven rail and flange wear. Stop the machine, inspect the alignment, and correct any bent or loose brackets immediately to prevent further damage.

Why is my excavator making grinding noises near the front of the track?

Grinding sounds often indicate dry bushings, failed seals, or debris stuck around the idler. Check for oil leaks, dirt buildup, or seized bushings. If seals are damaged, replace them promptly to avoid internal wear.

Why does the track feel too tight even after I adjust the tension?

If mud, clay, snow, or stones are packed around the idler, it cannot slide back to absorb tension. This makes the track feel tighter than it actually is. Clearing debris around the idler and track frame usually resolves the issue.

My excavator works mostly in wet clay. Do I need to check the idler more often?

Yes. Clay tends to pack tightly around the idler, restricting its movement. When the idler cannot slide properly, shock loads transfer directly into the undercarriage. Clean the idler area frequently to maintain smooth operation.