How Compact Rock Breakers Offer Exceptional Versatility

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

Rock breakers are a purpose-built attachment that can be used in excavators, backhoe loaders, and skid steer loaders. These attachments are popular for being versatile in construction, mining, quarrying, and demolition. On small urban projects, these powerful hydraulic breakers break down concrete and asphalt. While on larger sites, split slabs, tunnel rock, and break boulders into manageable pieces.

These hydraulic hammers are available in various sizes. Among them, compact rock breakers stand out. Instead of relying on sheer mass, compact rock breakers focus on controlled energy delivery, manoeuvrability, and flexibility.

In this article, we will be discussing:

What Makes Compact Rock Breakers So Adaptable on Job Sites

When we talk about versatility, it isn’t just doing one job well. The attachment should be able to handle different tasks, materials, and site constraints. So, operators don’t need to constantly change attachments for every task. This is a crucial factor when dealing with heavy machines like excavators or backhoe loaders.

Compact rock breakers come with exclusive design features and operational flexibility, which allows them:

Adaptability across varied site conditions

Construction or mining sites usually have different landscapes and challenges. Concrete slabs, sandy fields, mud or compacted rock each need special attention. That is why DOZCO rock breakers usually come with features such as:

- Optimised impact-to-weight ratios: This makes sure the attachment breaks down objects effectively with stressing smaller carriers.

- Nitrogen accumulators: They store rebound energy and stabilise hydraulic pressure during continuous work.

- Advanced dampening systems: With these systems, the machine or operator doesn’t feel the harsh vibration.

Work efficiency in confined and urban environments

For some projects like road repairs, service trenches, foundation work, or interior demolition, access is often limited. There is not enough space for the machine or attachments to move freely.

Compact rock breakers are preferred here due to their smaller physical footprint and better carrier balance.

This allows operators to:

- Position the breaker accurately in tight spaces.

- Start breaking from the coroner or edges instead of striking the centre, where fractures develop more easily.

- Maintain productivity without disturbing nearby structures.

Handling demanding tasks without oversizing equipment

Changing attachments every few hours impacts products. Despite the size, compact rock breakers can still perform the most demanding tasks, such as:

- Slab splitting,

- Trench tunnelling, and

- Breaking boulders.

The process is not done through brute force. Instead, operators hit the surface repeatedly at a controlled pace until the impacts create stress fractures inside the material.

DOZCO’s compact rock breakers also come with features like Anti-Blank Firing (ABF). The feature makes sure that the attachment releases energy only when the tool/chisel contacts the surface. This helps to avoid damage from idle blows and maintain consistent breaking performance.

Read more on:: choose right rock breaker for your machine

The role of tools/chisels in increasing the versatility of a rock breaker

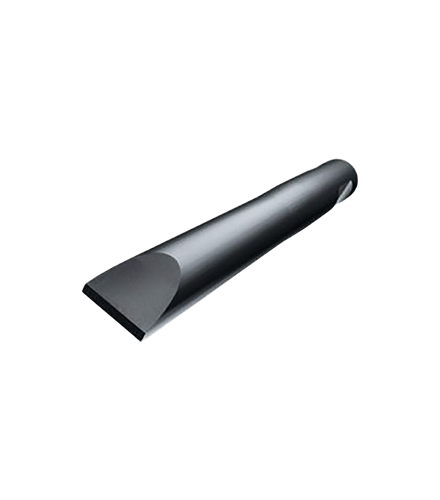

What makes a compact rock breaker more versatile is the tools/chisels. Since rock breakers work in different landscapes, choosing the right tool can improve the performance considerably. DOZCO offers multiple chisel options, allowing one breaker to perform several tasks simply by changing the tool, including:

- Wedge chisels: They push the material apart from the point of contact, so cracks open up and spread in a controlled direction. Wedge chisels are ideal for trenching and slab splitting where operators aim for clean, predictable breaks.

- Moil points: These tools deliver force through a narrow tip, so the breaker bites into concrete or solid rock. Each hit starts a crack at one point, and then deepens and spreads as you repeatedly blow the same spot.

- Blunt tools: These chisels spread impact over a wider area. They are mostly used for breaking material down by crushing rather than cutting into it. Whether it is reducing block size or breaking large boulders into manageable pieces, operators prefer them.

- Conical tools: They concentrate impact into a small contact area, so the tool penetrates dense or reinforced materials. This focused force helps start fractures where tougher material resists wider impact.

Wrap Up

The demanding nature of jobs like mining, quarrying or construction requires equipment that is versatile. Choosing the right one reduces the need to switch the machine or attachment in the middle of work and the time needed for it. Compact rock breakers stand out as a flexible attachment that can be attached to different machines for different jobs. At DOZCO, we are a reliable manufacturer of a wide range of excavator attachments, including rock breakers. Our rock breakers come in different sizes and weight ranges for contractors to match the breaker precisely to the carrier and application.

FAQs

What is the purpose of a rock breaker?

A rock breaker is used to break concrete, asphalt, and rock into smaller pieces using controlled hydraulic impact. These attachments are ideal for tasks like excavation, demolition, trenching, and material reduction without blasting.

What is the best rock breaker in the world?

There is no single “best” rock breaker. You have to consider application, carrier size, material hardness, operating conditions, and how efficiently the breaker matches the job requirements.

What is the best rock breaker size?

The size of a rock breaker usually depends on the carrier’s weight, hydraulic flow, and job type. You should choose the size wisely, as it leads to efficient breaking, stable operation, reduced wear, and better overall productivity.

What is the point of a rock crusher?

A rock crusher reduces large rocks into smaller aggregates for reuse in construction. Unlike rock breakers, crushers are stationary or fixed machines focused on material processing, not excavation.

What’s the capacity of a rock breaker?

Rock breaker capacity depends on impact energy, blow frequency, tool size, and carrier compatibility. For instance, DOZCO 300A rock breaker weighs around 215 kg, suitable for 2.4-4 ton machines with an impact rate of 600 – 1100 bpm (blow per minute).