5 Signs Your Excavator Hammer Needs Repair or Replacement

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

If your bread and butter comes from the heavy-duty industry like construction or mining, you know how harsh it can be. With the rough landscape and long shift hours, it doesn’t just put a toll on workers but also the machines and attachments as well.

Excavator Hammer, for instance, is used to break hard rock and reinforced concrete. Most of these rock breakers run on high hydraulic pressure and need every internal component functioning smoothly to avoid slipping, overheating, or losing impact power. However, the dust storms, heat waves, heavy vibration, and long shifts can wear down the attachment and its components.

In the beginning, the attachment shows an early signal. However, if you don’t identify or neglect those symptoms, it can end up with sudden failures. This article breaks down how a hammer works, which parts needs to withstand the most, and the signs that tell you it’s time to repair or replace something before the damage spreads:

How an Excavator Hammer Works

Most excavator hammers are powered by hydraulic systems. They convert hydraulic flow from the excavator into high-speed impact energy. So, when an operator uses a rock breaker, the chisel touches the surface at high-speed, repeatedly causing the surface to shatter.

Since it is a complicated and high-energy process, you need to be very careful to avoid internal component wear:

- Clean hydraulic flow,

- The right pressure settings, and

- Correct tool positioning.

Because even small internal issues can ripple through the entire system, reducing impact power and stressing the carrier.

Read more on: How Rock Breakers Operate

Key Components of an Excavator Hammer & Why They Wear

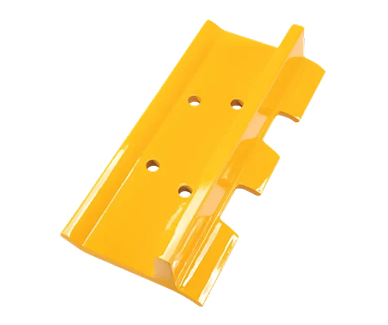

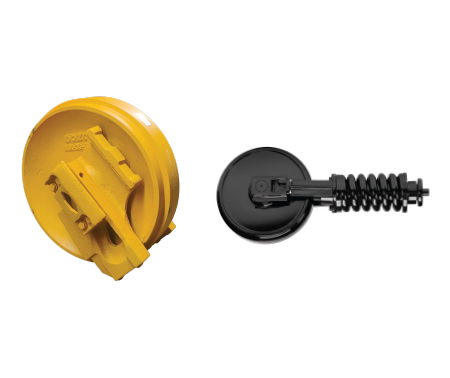

Hammers are manufactured with different major parts that determine their performance and lifespan. While all components of a hydraulic rock breaker work together to deliver a powerful blow, not all wear out equally. Some components naturally wear out more quickly because of constant friction, vibration, and repetitive impact.

Let’s take a look at the different hammer components:

- Piston: It is the component that generates the actual hammering energy.

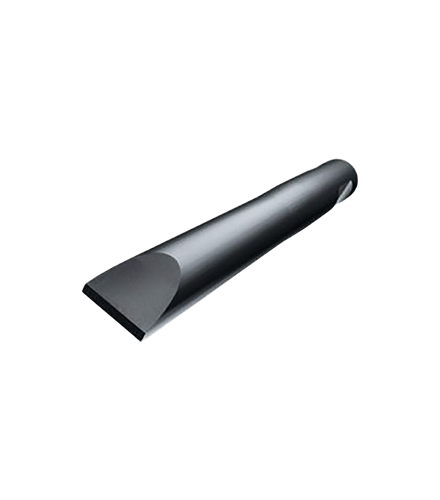

- Tools/Chisels: They contact the material and transfer that energy into the rock. Since they constantly take direct hits for hours every day, they need to be repaired and replaced the most.

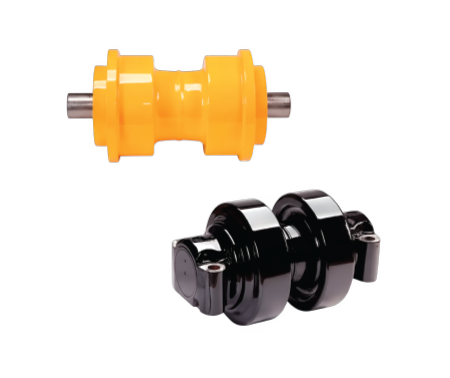

- Wear bushes: Make sure the tool and stop metal-to-metal contact. These components usually degrade faster because they are in direct contact with the tool and constantly guide its movement.

- Dampers: They absorb vibration and protect the excavator boom. Since they compress thousands of times per shift, with time, they slowly lose their ability to absorb vibration.

- Rod pins: They hold the tool in place and ensure stable alignment. Sometimes, operators use the hammer at the wrong angle. This causes the tools to shift inside the front heading and wear down rod pins.

- Accumulator: Regulates pressure spikes and protects the hydraulic system.

- Front Cover, Back Head, Seals: These components keep everything tightly assembled, preventing leaks or misalignment under heavy loads. However, the front cover faces constant dust, grease, and shock loads and starts to wear away. It extends the gap between the tool and the cover, which can affect accuracy, reduce impact efficiency, and increase stress.

5 Signs Your Excavator Hammer Needs Repair or Replacement

It’s rare for a hydraulic hammer to fail without warning. There are signs here and there, and if you know what to look for, you can avoid the expensive repair and replacement from happening frequently.

1. Loss of Impact Power

If you are operating the same machine and attachment, you can easily identify the subtle difference when the hammer starts hitting softer or takes longer to break material. They occur due to:

- Worn bushes,

- Low nitrogen pressure, or

- Malfunctioning piston.

Don’t avoid it. Check yourself or reach out to the service centre.

2. Excessive Vibration Reaching the Excavator Boom

Using hydraulic hammers for mini excavators or large ones causes vibration. But if the attachment is in good condition, it absorbs most of the recoil. When bushes or dampers wear out, that shock travels straight into the boom pins and cylinders. Operators may feel a “kickback” or unusual shaking. If this is happening with your rock hammer, you should consider replacing it.

3. Chisel Movement

The tools/chisel of a hydraulic breaker can last 150-500 hours, depending on rock hardness, operator skill, maintenance, and hammer size. If you see any sign of the chisel wobbling or rattling inside the front head, then it might be due to worn out bushes. Check and take immediate action, or it can cause tool breakage, cracked front heads, or even piston damage.

4. Oil Leaks, Gas Loss, or Overheating

Sometimes oils drip from the hammer; it is a sign that the seal might not be working properly. Besides, if the hoses vibrate during operation or nitrogen pressure drops below specification, you need to service the accumulators or internal valves. Overheating during normal operation also indicates restricted flow, incorrect pressure settings, or worn internal components.

5. Unusual Noise

Hydraulic breakers usually create a loud impact sound when they hit a hard surface. But if you’re familiar with these attachments, you can easily tell if something sounds wrong. Look into what might be causing the unusual noise.

6. Frequent Blank Firing

New or untrained operators often blank fire. It can also occur if you don’t pay attention. Since the hammer hits without the tool contacting the material, it causes even faster wear than what is caused by worn bushings, improper positioning, or faulty internal valves. That is why DOZCO rock breakers come with ABF (Anti-blank firing system) to protect your attachment from premature wear.

Tips to Avoid Frequent Excavator Hammer Repair & Replacement

A rock hammer lasts much longer when it’s fitted with the right parts and operated the right way. Here are simple habits that make a big difference on Australian job sites.

- Choose a rock breaker made of high-quality bushes, tools, and dampers. Because cheaper parts wear out quickly under abrasive rock, heat, and long working hours.

- At DOZCO, our rock breaker components are made from hardened steel with tight tolerances. Hence, they can hold their shape under heavy load and protect the piston and cylinder.

- Lubricate the hammer every two to three hours to cut down friction and stop the tool from scraping the bush.

- Keep the chisel at a ninety-degree angle on the work surface and reposition often to prevent overheating.

- Check nitrogen pressure, bush clearance, rod pin condition, and through bolt tightness to stop small issues from turning into internal damage.

- Match the excavator’s hydraulic flow and pressure to the hammer’s requirements so seals, pistons, and valves stay safe.

The Bottom Line

Large, medium and mini excavator hammer attachments are designed to withstand the demanding nature of the tasks. But they still need regular repairs and replacements. When operators understand how it works, which components wear fastest, and what early signs to look for, they can spot issues long before the hammer breaks down and avoid costly replacements and breakdowns.

FAQs

How often should I service an excavator hammer?

Most hammers need daily greasing, weekly checks, and a full inspection every 250–300 hours. Mining sites may require more frequent servicing due to heavier loads and abrasive rock.

Why is my hydraulic hammer losing power?

Loss of power usually comes from worn bushes, low nitrogen pressure, or incorrect hydraulic flow. Early checks prevent piston or cylinder damage and restore the hammer’s impact strength.

Should I repair a worn chisel instead of replacing it?

No. Repairs change the chisel’s hardness and make it brittle. A repaired tool often fails early and can damage pistons, bushes, and the front head. Replacement is safer and cheaper.

What causes excessive vibration in a hydraulic breaker?

Excess vibration usually indicates worn dampers or bushes. When these components can’t absorb impact, the shock travels into the excavator boom, risking serious structural damage.

Do rock breakers make noise during operation?

Yes, they produce loud impact noise. However, unusual metallic sounds or irregular clicking usually signal internal wear, tool misalignment, or bush failure.