Leading Construction & Mining Rollers Supplier in Australia

For the undercarriage system of a crawler machine, rollers are vital components. They are responsible for carrying the machine’s weight, guide the track chain, and help distribute impact and shock loads, especially when moving through uneven or high-impact surfaces. DOZCO specializes in designing and manufacturing undercarriage parts for heavy equipment. We offer single‑ and double‑flange bottom rollers as well as carrier rollers for crawler machines from 1 ton to 250 tons. We are a trusted manufacturer and global supplier of high-performance undercarriage parts for heavy equipment, including hydraulic excavators, and dozers of diagonal brace and pivot shaft type, and elevated sprocket machines. Our product range includes Caterpillar rollers, Komatsu track rollers, and other components engineered for various OEMs.

Key Features

High load-bearing roller design

Surface-hardened alloy steel shells

Precision-sealed floating seal system

OEM-compatible, ISO-certified rollers

Understanding Rollers

- Types

- Key Components

- Maintenance Insights

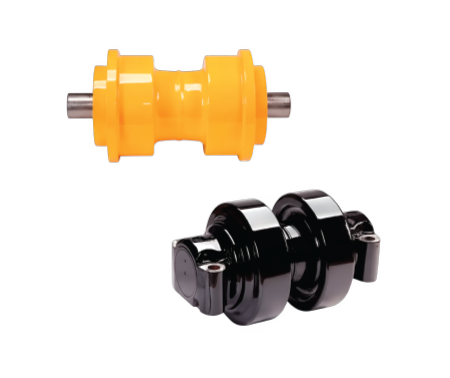

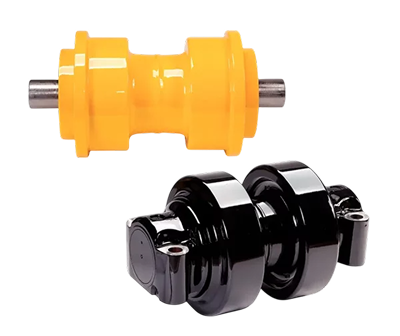

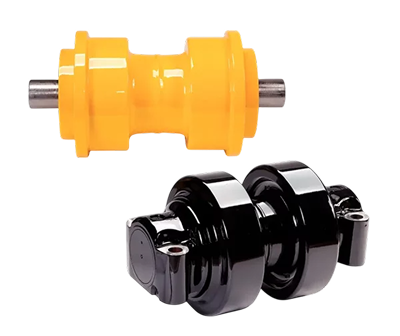

Lower (Track) Rollers

Lower rollers, also known as track or bottom rollers, are mounted beneath the track frame. They carry the machine’s operating weight and guide the track chain as it moves over uneven ground. These components are often the first to absorb shock loads from rough terrain. At DOZCO, we manufacture ISO-certified dozer track rollers.

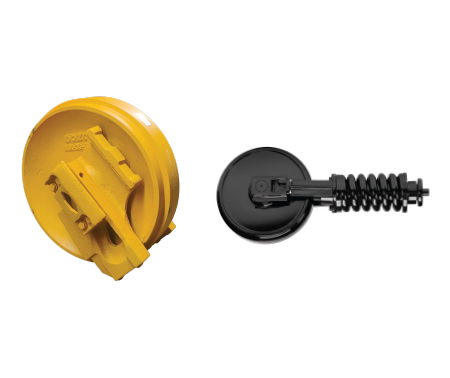

Carrier Rollers

Carrier rollers are positioned along the upper side of the track frame. Their function is to support the return side of the track chain between the sprocket and front idler. Proper carrier roller placement helps control track sag, reduce vibration, and maintain smooth track movement. At DOZCO, we manufacture and supply OEM-compatible excavator carrier rollers in Australia.

Roller Shell

The roller shell is the outer surface that remains in constant contact with the track chain. It is manufactured from high-strength alloy steel and surface-hardened through induction to withstand abrasion, impact, and prolonged rolling contact in harsh site conditions.

Shaft

Each roller rotates around a stationary shaft. This fixed shaft design improves structural stability and allows consistent load transfer across the undercarriage. In carrier rollers, the shaft often includes an internal oil reservoir to ensure continuous lubrication during operation.

Floating Seals

Floating seals are installed at both ends of the roller shell. Their function is to keep lubricant sealed inside while preventing dirt, dust, mud, and debris from entering. Optional rubber ring variations allow these seals to perform reliably across different temperature ranges and site environments.

Brackets

The shaft ends are secured into heavy-duty brackets that lock the roller assembly firmly to the track frame. These brackets prevent unwanted movement under load and help maintain proper roller alignment during operation.

Bushings / Bearings

Bronze bushings are press-fitted inside the roller shell and rotate around the shaft. During operation, oil forms a thin film between the bushing and shaft, reducing friction and heat build-up. On selected carrier roller models, oil-supplied roller bearings may be used instead to further reduce friction and improve efficiency.

Daily Inspection

Proper alignment and regular inspections are essential for extending roller and overall undercarriage life.

Regular cleaning

Soil packing around rollers can restrict movement, leading to dry joints, oil leaks, and uneven wear on rollers and track chains. Regular checking and cleaning keeps movement smooth.

Checking track tension

It causes mismatched wear between link rail sides and roller flanges, affecting machine stability.

Track alignment

Track misalignment accelerates wear on inboard and outboard roller flanges as well as sprocket teeth.

Temperature Monitoring

During extended travel, such as walking the machine for more than 100 metres or three minutes, roller temperatures should be monitored. If any roller exceeds ambient temperature by 20°C, pause operation and allow cooling.

Applications of Rollers

Carry machine weight evenly across tracks

Guide track chain for smooth travel

Absorb shock from uneven terrain

Reduce vibration and undercarriage stress

Why Choose Rollers from DOZCO

why choose Us

Exceptional wear resistance with alloy steel shells

Precision-machined shafts and bushings for smooth operation

Broad compatibility with leading OEM brands

Tested to meet global standards for durability and reliability

Compatible Brands

(*OEM names or part numbers are for reference only. )

Caterpillar (CAT)

Komatsu

Hitachi

Volvo

Hyundai

Doosan

JCB

Frequently Asked Question

Q. What does DOZCO Australia specialize in?

DOZCO Australia specializes in supplying world-class attachments and spare parts for excavators and dozers, including rock breakers, augers, chisels, and undercarriage parts. Backed by four decades of global expertise, we ensure reliable solutions for mining, quarrying, and construction needs.

Q. Where is DOZCO Australia located?

Q. How extensive is DOZCO’s global presence?

With over 750 employees worldwide and more than 25,000 parts in stock, DOZCO operates on a global scale. Our combination of international manufacturing and local Australian support ensures trusted service and product availability.

Q. What industries does DOZCO serve?

DOZCO caters to key industries such as mining, quarrying, civil construction, and infrastructure development. Our range of attachments and parts is designed to maximize efficiency, durability, and productivity in heavy-duty operations..

Q. How can I purchase DOZCO products in Australia?

You can connect with our local team in Melbourne or Brisbane to explore our product range. DOZCO provides expert consultation, product availability details, and after-sales support to ensure you find the right attachment or spare part for your needs.