High-Performance Idlers for OEM Undercarriage Systems

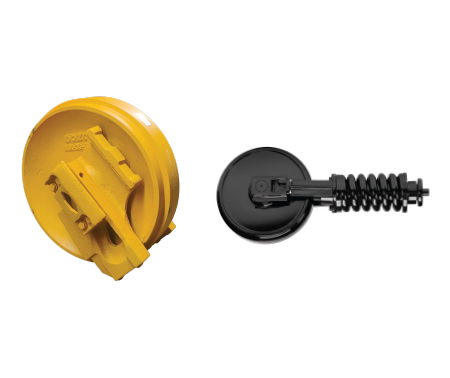

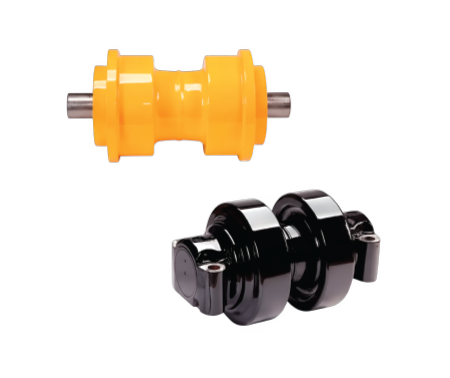

In the heavy-duty sector, idlers are reliable undercarriage parts. These undercarriage parts ensure smooth redirection of the track from the sprocket to the front of the frame. DOZCO manufactures high-quality undercarriage parts for heavy equipment. This includes excavator idler wheels, along with front idler assembly and rear idler assembly for dozers, designed to guide the track chain and maintain proper alignment. The front idler is a large wheel at the front of the track frame. It acts as a pivot point, redirecting the track chain back toward the sprocket. A rear idler, on the other hand, is located at the rear of the undercarriage. It makes sure that the tracks are properly aligned and tight to avoid the risk of derailment during operation.

Key Features

Heat-treated for long wear life

Engineered for heavy-duty loads and shock absorption

Available in cast and fabricated versions

Designed to Meet International Standards

Understanding Idlers

- Key Components

- Maintenance Insights

Idler Shell

The idler shell is what is exposed to constant impact. Therefore, it is surface-hardened through induction to add strong wear resistance in challenging environments.

Shaft

The idler rotates around a stationary shaft. The shaft includes an internal oil reservoir that maintains continuous lubrication during operation.

Floating Seals

The seals are placed at each bushing end, designed to keep lubricant inside and contaminants like dirt and debris out. It often comes with optional rubber ring variations for better performance in different climate conditions.

Brackets

The shaft ends are mounted into heavy-duty brackets that enable free rotation. These brackets slide inside the track frame, supporting the recoil spring system and helping absorb shock loads, thereby protecting the undercarriage.

Bushings

Bronze bushings are pressed into the idler shell and rotate around the shaft. During rotation, oil forms a film between the bushings and shaft to reduce heat generation and friction that can lead to wear.

Toe-In / Toe-Out Misalignment

Toe-in or toe-out misalignment typically occurs due to a bent idler yoke or a distorted idler box section. These structural deformations can lead to uneven wear on the sides of the link rail, which over time also damages the idler flanges and the flanges of the first track roller. It is essential to thoroughly inspect the undercarriage components for any bends or warping. If the components are only slightly out of shape, they only need straightening. However, if structural recovery is not feasible, the idler yoke needs to be replaced to restore proper alignment and prevent further wear.

Lateral Displacement

Improper shimming during installation causes lateral displacement of the excavator idler wheel. When the shims are incorrectly adjusted, it can shift the idler sideways, causing excessive wear on the idler flanges, track links, and roller flanges. Over time, this misalignment causes additional stress on the track assembly, which impacts its longevity. Adjusting shims properly and maintaining a clearance of 0.5 to 1 mm between the guide plates and the track frame allows proper movement without causing misalignment.

Twist / Tilt Misalignment

Twist or tilt misalignment occurs if inner or outer support box sections are vented or from uneven wear on the idler wear plates. This can lead to abnormal wear patterns, especially on the idler flanges and the inner sides of the track link rails. Leaving it unattended can also impact other components of the undercarriage system. The primary option is to straighten the support box or yoke. In case that is not possible, it is recommended to proceed with component replacement.

Applications of Idlers

Specially engineered construction idlers offer better performance in Heavy-duty construction sites

Mining idlers are designed to withstand rugged mining operations

Suitable for infrastructure and earthmoving projects

Why Choose DOZCO Idlers for Your Undercarriage System

Heat-treated for long wear life

Engineered for heavy-duty loads

Available in cast and fabricated versions

Compatible with major OEM brands (e.g., Komatsu idlers)

Compatible Brands

(*OEM names or part numbers are for reference only.)Caterpillar, Komatsu, Volvo, Liebherr, Doosan, Kobelco, Sumitomo, Hitachi, Hyundai, YANMAR, CASE, John Deere, and more.

Caterpillar (CAT)

Komatsu

Hitachi

Volvo

Hyundai

Doosan

JCB

Frequently Asked Question

Q. What does DOZCO Australia specialize in?

DOZCO Australia specializes in supplying world-class attachments and spare parts for excavators and dozers, including rock breakers, augers, chisels, and undercarriage parts. Backed by four decades of global expertise, we ensure reliable solutions for mining, quarrying, and construction needs.

Q. Where is DOZCO Australia located?

Q. How extensive is DOZCO’s global presence?

With over 750 employees worldwide and more than 25,000 parts in stock, DOZCO operates on a global scale. Our combination of international manufacturing and local Australian support ensures trusted service and product availability.

Q. What industries does DOZCO serve?

DOZCO caters to key industries such as mining, quarrying, civil construction, and infrastructure development. Our range of attachments and parts is designed to maximize efficiency, durability, and productivity in heavy-duty operations..

Q. How can I purchase DOZCO products in Australia?

You can connect with our local team in Melbourne or Brisbane to explore our product range. DOZCO provides expert consultation, product availability details, and after-sales support to ensure you find the right attachment or spare part for your needs.