How Track Link Assembly Affects the Performance of Excavators and Bulldozers

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

Did this ever happen to you? You’re halfway through a digging cycle when the numbers stop adding up. The bucket takes longer to fill, the machine moves with a slight delay, and the cycle time quietly stretches. For any experienced operators, it’s easy enough to notice the minor changes.

You get an idea that something in the undercarriage is not transmitting power efficiently. And when a machine starts to lose efficiency like this, the root cause is not always the hydraulics or the engine. It usually comes from the undercarriage. More specifically, the undercarriage parts – Track Link Assembly (TLA). When the TLA starts wearing out or falling out of alignment, the entire crawler system resists motion.

In this article, we will discuss what a TLA is, why it matters, and how it directly influences the performance of excavators and bulldozers.

What is a Track Link Assembly

Track Link Assembly (TLA) is the chain system that is essential for tracked dozers and excavators to travel through the surface. It supports the full machine weight, transfers engine power to the ground, and guides the machine as it digs, pushes, and travels.

The undercarriage parts include:

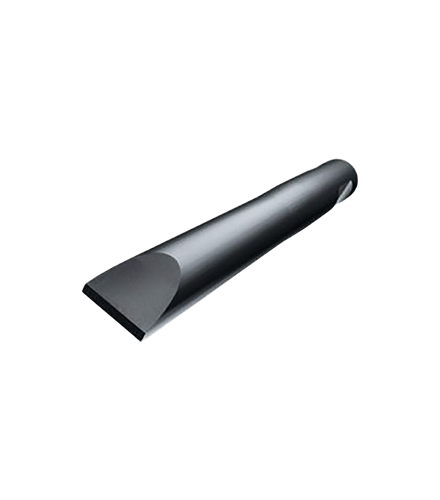

- Track links that form the chain structure.

- Pins and bushings that allow rotation and maintain pitch.

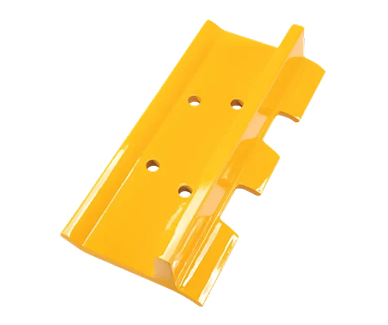

- Track shoes provide grip and flotation.

- The master link allows installation and removal.

- Seals in sealed/lubricated systems to retain oil.

Types of Track Link Assemblies

Depending on the working conditions, the design of the track link assembly changes. Here are the three major types used across excavators and bulldozers:

-

Dry Chains

Dry chains are simple and cost-effective, with no internal lubrication. They suit lighter applications where machines don’t operate continuously under high loads. However, they also tend to wear faster and require closer inspection intervals.

-

Sealed Chains

These chains contain oil sealed inside each pin-bushing assembly. The lubrication reduces internal friction, minimizes wear, and extends service life. Sealed chains are ideal for general construction where uptime and reliability matter.

-

Sealed & Lubricated (SALT) Chains

These undercarriage parts are also known as salt-type chains. They are built for heavy, high-impact, and abrasive working conditions. SALT chains offer superior wear resistance and lower friction over long operating hours. DOZCO is among the youngest Indian manufacturers offering this advanced chain type.

Pitch Range

TLA pitch sizes vary based on machine size and application. At DOZCO, we manufacture TLAs from 125 mm to 280 mm pitch, covering a wide range of dozers and excavators.

How Track Link Assembly Affects Machine Performance

These undercarriage parts play a crucial role in a machine’s overall performance. Here’s how:

-

Premature Wear of Pins, Bushings, and Links

When these components wear quickly, the machine loses smooth rotation around the pin-bushing joint. Friction rises, the engine compensates with more power, and cycle times quietly increase. Over time, you’ll feel the machine becoming less responsive during travel and pushing.

How the TLA causes it:

Common reasons include:

- Insufficient lubrication (dry chains)

- Seal failure (sealed chains)

- Misalignment of the chain

- Operating with incorrect track tension

As wear progresses, pitch changes and internal stress rise at every rotation.

Maintenance insight:

Routine pitch measurement, bushing diameter checks, and temperature monitoring for dry joints help catch early wear. Upgrading from dry to sealed or SALT chains can dramatically extend component life in heavy-duty environments.

-

Loss of Traction and Digging Efficiency

Reduced traction decreases the machine’s ability to convert hydraulic force into ground engagement.

You’ll notice:

- Weaker digging penetration

- Slower pushing performance

- More track slip on soft or uneven terrain

This means more passes, lower output, and wasted fuel.

How the TLA causes it:

Loss of traction is triggered by:

- Pitch extension

- Link rail height wear

- Uneven or low grouser height

- Bushing ovality

- Distorted or loose track shoes

When these conditions occur, the chain loses stiffness and fails to maintain uniform contact with the ground. Torque transfer becomes inconsistent, and micro-slips reduce effective traction.

Maintenance insight:

Measure pitch often, check grouser dimensions, and maintain correct sag/tension.

Re-grousering or replacing worn track shoes restores traction in demanding soils.

-

Higher Fuel Consumption

Productivity impact:

Increased fuel burn signals that the machine is fighting internal resistance instead of producing forward motion. Travel slows, hydraulic load rises, and efficiency drops even when external conditions haven’t changed.

How the TLA causes it:

Fuel consumption spikes when:

- Bushings wear and friction rises.

- Track tension is too tight.

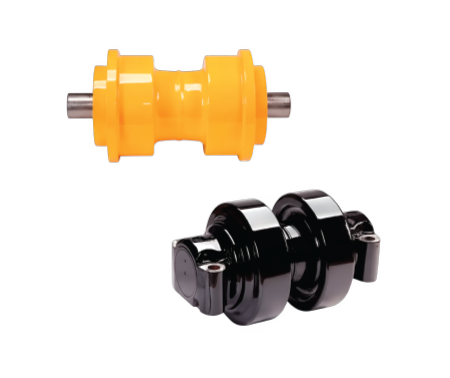

- Links and rollers lose alignment.

- Bushings become oval.

- Rollers develop flat spots.

Every rotation demands more power, and the engine compensates by burning more fuel.

Maintenance insight:

Regular checks of undercarriage parts, such as roller diameter, bushing wear, and chain pitch, keep resistance low. Correct tensioning and choosing SALT chains for heavy work significantly stabilizes fuel use.

-

Machine Instability and Rough Travel

When a machine is unstable, it starts to shake, move unevenly, or struggle to go in a straight line. This reduces operator comfort and makes fine grading or precision digging harder.

How the TLA causes it:

Instability often develops when:

- Link rails wear unevenly.

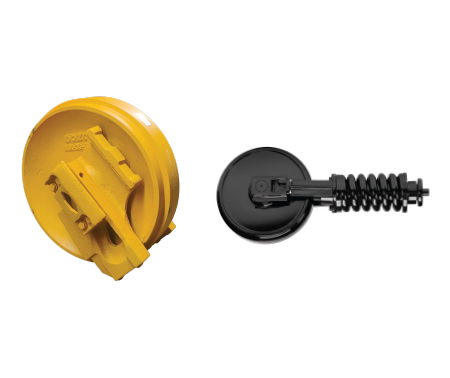

- Rollers flatten or seize.

- Pitch variation disrupts sprocket engagement.

- Bushings develop tight spots.

- Track shoes loosen or misalign.

Once the chain loses uniform rolling behavior, the machine begins to oscillate and transmit shock through the frame.

Maintenance insight:

Measure link rail height, check rollers for flat spots, and inspect pitch regularly. Correct tension and proper shoe alignment restore smoother travel.

-

Frequent Breakdowns and Increased Downtime

Breakdowns halt operations, delay job progress, and add steep repair costs. Undercarriage failures are among the most expensive and time-consuming to fix.

How the TLA causes it:

Breakdowns occur due to:

- Pin or bushing failure

- Chain derailing

- Seized joints

- Broken or loose shoes

- Cracked links

- Roller seizure

Failures in one component often trigger damage in others, amplifying downtime.

Maintenance insight:

Frequent pitch checks, bushing inspections, and monitoring joint temperature prevent costly breakdowns. In high-impact environments, upgrading to SALT chains drastically improves reliability.

-

Excessive Noise, Vibration, or Chain Jumping

Metallic clicks, grinding, or rhythmic vibration are early signs of internal TLA issues.

If ignored, they often lead to chain jumping, a dangerous condition that can result in derailment.

How the TLA causes it:

Noise and vibration usually come from:

- Pitch variation

- Worn sprocket teeth

- Link rail wear

- Oval bushings

- Seized or flattened rollers

- Misaligned shoes

These issues disrupt chain seating and create inconsistent engagement with the sprocket.

Maintenance insight:

Check pitch at multiple points, monitor sprocket wear, and inspect rollers frequently. Proper shoe torque and regular cleaning reduce vibration and prevent jump events.

Closing Thought

Undercarriage parts like the Track Link Assembly may sit low on the machine, but it impacts everything you feel during digging, pushing, or travelling. When the TLA stays in good condition with correct pitch, healthy bushings, and proper tension, the machine runs smoother, uses less fuel, and delivers consistent traction. When it’s ignored, performance drops long before a breakdown occurs.

For operators, simple routine checks prevent major failures. For maintenance teams, accurate wear measurements protect the entire undercarriage. And for buyers, choosing the right chain type dry, sealed, or SALT directly affects cost-per-hour.

FAQs

My excavator feels slower during digging. Does that mean the TLA is worn?

Yes. When the machine feels heavier or slower during digging or pushing, it often means the pin–bushing joints inside the Track Link Assembly are not rotating smoothly. This creates resistance and forces the engine to work harder, which slows down the cycle. It’s one of the most common early signs of TLA wear.

The machine pulls to one side while travelling. Which undercarriage part should I check first?

Start by looking at the link rail height on both sides, because uneven wear can make the machine drift. After that, check the rollers, since a seized or flattened roller can pull the chain off-line. Track tension differences between the left and right sides, and improper sprocket engagement, also commonly cause tracking deviation.

I hear a clicking sound at low speed. Is it dangerous?

A clicking or ticking sound usually indicates early pitch variation, an oval bushing, a dry joint, or even a loose shoe. It may not be immediately dangerous, but it is a warning sign. If ignored, these small issues can turn into chain jumping or uneven sprocket wear, so they should be checked soon.

The chain looks fine, but performance is dropping. What should I test?

Visual checks only tell part of the story. You should measure the pitch across multiple chain segments, check the bushing diameter, verify the roller diameter, and inspect the grouser height. A quick temperature check using an infrared thermometer can also reveal dry or seized joints that don’t show externally.