How to Maintain Your Machine’s Undercarriage?

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

Excavator or dozer undercarriage parts need regular inspection and maintenance. Since the machines work in harsh conditions and regularly come in contact with dust, debris, and rocks, this can cause wear and tear. Overlooking such factors can end up in a sudden breakdown and may also jeopardize your workspace safety.

This article explores how often your machine’s undercarriage needs maintenance and inspection, and how to perform them:

Essential Undercarriage Parts

An undercarriage is made up of many individual components that all work together to keep the machine stable, mobile, and efficient. Here are the key parts every operator should know:

- Track Chains & Links

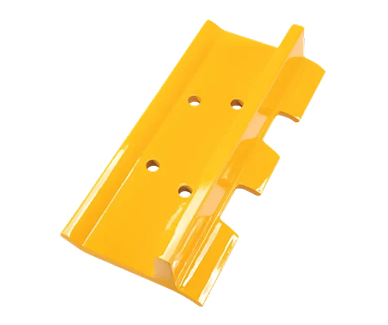

- Track Shoes

- Track Pins & Bushings

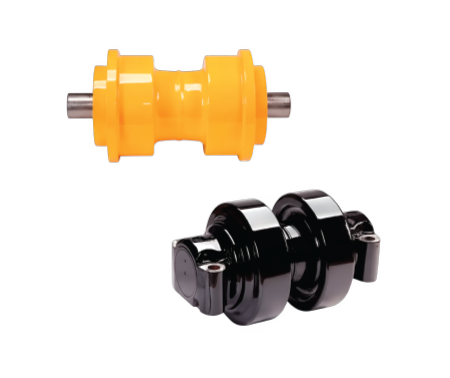

- Rollers (Carrier & Track Rollers)

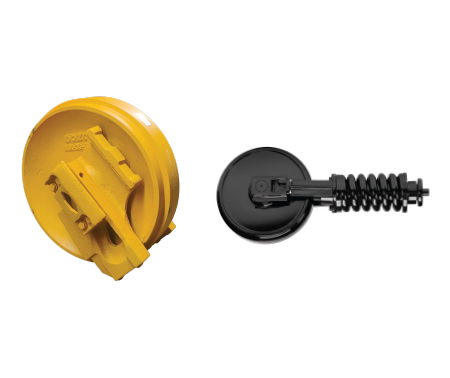

- Idlers

- Sprockets

Maintenance by Time Interval

An excavator or dozer undercarriage parts need maintenance and inspection daily, weekly, and monthly.

1. Daily Inspection

As previously mentioned, the undercarriage touches the ground all the time. So, mud, soil or debris may get stuck in the undercarriage parts, which can cause

- Oil leaks,

- Loose bolts, or

- Abnormal noises

That is why operators must thoroughly inspect the undercarriage daily or after every 10 operating hours to make sure it is in working condition.

2. Weekly Inspection

Undercarriage parts like the track pins or chains need inspection weekly or every 50 service hours. It is important as

- Pins can dry out after a week of use.

- Track tension might become loose, increasing wear on sprockets, rollers, and shoes.

Weekly checks help keep the machine efficient and prevent the track from derailing.

3. Monthly Inspection

Monthly inspections and maintenance checks are done every 250 operational hours. The bolts of excavator or dozer undercarriage parts naturally loosen over time due to vibration and heavy loads. If they aren’t checked, a loose track shoe can damage the chain or even fall off during work. Monthly torque checks make sure the entire undercarriage stays tight and safe.

How to Perform a Walk-Around Inspection

Any experienced operator or contractor knows the importance of a walk-around inspection. This is a non-negotiable part before starting any operation. Here are a few steps to follow:

- Listen for any abnormal noise while moving the machine slowly in an open area.

- Visually check carrier rollers, track rollers, and idler wheels, and look for oil leaks. Generally, in sealed & lubricated track chains, the pins are factory-sealed with grease or oil. If there is any leakage, it may indicate internal failure.

- You should also look for wear and loose bolts in the track surface, shoes, sprockets, and links. If any issues like wear or leakage are found, consult with your Italtractor ITM Dealer.

While regular maintenance increases the longevity of undercarriage parts, it is essential to replace them when necessary. DOZCO is a leading manufacturer and supplier of undercarriage parts in Australia.

Read more: https://dozco.com.au/high-quality-excavator-undercarriage-parts/

Detailed Part-by-Part Maintenance

Beyond daily, weekly, and monthly intervals, certain undercarriage parts require more specific attention.

1. Rollers, Idlers, and Track Surfaces

- Check carrier rollers, track rollers, and idler wheels for leaks.

- Inspect track chain pins in sealed and lubricated chains; any oil or grease leakage signals failure.

- Look at track shoes, sprockets, and links for wear or looseness.

2. Track Pins (Sealed & Lubricated Chains)

- During operation, listen for squeaks or squeals. These often mean the pin joint is dry.

- After the operation, touch each pin or bushing lightly with the back of a gloved hand. If the pin feels very hot (above ~50 °C / 120 °F), then it is an indication of dry joints.

- Many operators use infrared thermometers, as it is a much safer, faster way to detect hot pins.

3. Track Tension Check & Adjustment

Correct track tension reduces wear and prevents derailment. However, the methods vary by machine:

- Elevated Sprocket Machines

- Lift ripper attachment before measuring.

- Measure sag with a string stretched between the sprocket & front idler.

- If there are no carrier rollers, measure sag directly between the sprocket & idler.

- If carrier rollers, measure average dimensions from carrier roller to idler.

- Compare with values in your maintenance manual, adjust accordingly.

- Lower Sprocket Machines

- Move the machine forward twice its length, stop without brakes, shut engine.

- Place a straight edge across grousers between the carrier roller & idler.

- Measure clearance between the straight edge & lowest grouser tip.

- Compare with the manual, adjust if necessary.

4. Track Shoe Bolt Torque Check

Bolts loosen naturally with vibration and heavy use.

- For new chains, check the torque after 50 hours, then every 250 hours.

- In heavy-duty operations, check every 100 hours.

- Always use the correct torque wrench, tighten evenly, and stop once the required torque is reached.

5. Split Master Link Assembly

This step is critical when replacing chains or shoes.

- Clean all mating faces and bolt holes.

- Hand-fit bolts first to avoid thread damage.

- Position the shoe, align correctly, and tighten bolts in sequence using a torque wrench.

- Always verify the bolt class (11.9 / 12.9 / 13.9) and apply proper torque.

- Recheck torque after 100 hours, then again after 500 hours.

Final Thoughts

Maintaining excavator and dozer undercarriage parts is not just about extending the life of components; it’s about keeping your machine safe, efficient, and reliable on tough job sites. From track chains and rollers to sprockets and idlers, each part plays a critical role in overall performance. Regular walk-around inspections, scheduled servicing, and correct torque checks can prevent costly breakdowns and improve productivity.

Frequently Asked Questions

What are the essential dozer undercarriage parts?

The main undercarriage parts include track chains & links, track shoes, pins & bushings, rollers (carrier & track), idlers, and sprockets. Each part works together to keep the machine stable, mobile, and efficient.

How often should I inspect my machine’s undercarriage?

You should perform daily walk-around inspections, weekly checks of track pins and tension, and monthly torque checks on bolts. This ensures safety, reduces wear, and prevents unexpected breakdowns.

Why is track tension so important?

Correct track tension helps reduce wear on sprockets, rollers, and shoes. Loose or overly tight tracks can cause derailment, premature wear, and costly repairs.

How do I know if my track pins or bushings are failing?

Listen for squeaks or squeals during operation. Hot pins (above 50 °C / 120 °F) or oil leakage from sealed and lubricated chains often indicate dry or failing joints.

What are common signs that undercarriage parts need replacement?

Look for oil leaks, abnormal noises, excessive wear on track shoes or sprockets, loose bolts, or derailing tracks. If you notice these, consult your supplier for replacement.