How to Extend the Life of Excavator Undercarriage Parts in Harsh Conditions

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

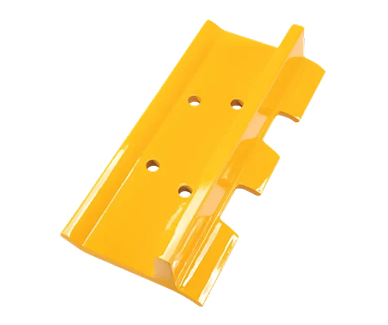

Tracked excavators mostly work in harsh environments. Digging in rocky hill areas, moving clay in a rainy site, or working in a sand mine can take a toll on your machine’s excavator. In fact, 40–60% of your excavator’s maintenance cost comes from excavator undercarriage parts wear. So, regular maintenance isn’t an option.

Harsh conditions make the wear faster. But with the right inspection habits and a few smart operating choices, you can stretch the life of your rollers, idlers, chains, and shoes far beyond the usual limit.

In this article, we will discuss what causes undercarriage wear in harsh conditions and how you can avoid it:

Why Harsh Conditions Damage the Undercarriage Faster

Different job sites create different stress. Here are the most common reasons:

Sand, Rock, and Abrasive Soil

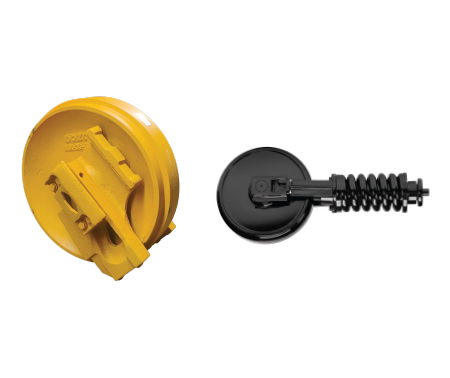

Undercarriage carriage is usually made of high-quality alloy steel. However, when working in sand and rock, it can grind down metal surfaces. The excavator undercarriage part, idler tread wear becomes faster in abrasive material, high packing, and high machine speed. When hard rock and quartz enter between sprocket teeth and bushings, it cuts down bushing wall thickness and causes cracks.

Mud Packing and Clay Build-Up

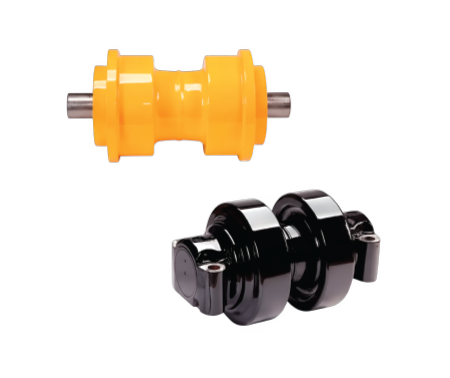

Depending on your project, excavators often have to work in mud, clay, and sticky soil. These can get under rollers and idlers. As a result, rollers seize, leading to flat spots and flange wear. Even the track shoes become loose because of packing, causing cracks and deformation.

Side-Slope and Hilly Work

When working on slopes or hills, the machine sits tilted, so the entire load moves to one side. It causes excavator undercarriage parts like sprockets to wear faster and also misalignment. Idler flange side wear increases on slopes.

Frequent Turning & Sharp Pivoting

In many cases, the excavator has to take sharp turns. These tight turns twist the track chain. It leads to scalloped link wear, roller wear, and grouser wear.

Reverse Travel

Operating in reverse wears bushings much more than moving forward. Reverse-side bushing wear is naturally higher and faster.

Wrong Track Tension

While this doesn’t happen due to harsh conditions, it is one of the major reasons for excavator undercarriage parts wear. When the tracks are too tight or too loose, it causes side wear, snaky chain idler and roller wear, and pitch extension.

Regular Inspections That Extend the Life of Excavator Undercarriage Parts

Regular checks are the cheapest way to reduce wear. Even in harsh conditions, small daily habits make a big difference.

Daily Walk-Around (10-Minute Habit)

Though it may feel tiresome, a quick check before starting work helps catch early damage.

Look for:

- Oil leaks from rollers, idlers, and seals

- Dry joints in sealed pins

- Loose bolts

- Cracks in shoes or links

- Abnormal noises while moving slowly

If you see leaking oil or hear squeaking, treat it as a warning.

Clean the Undercarriage Daily

If you are working in muddy or sandy areas, cleaning the undercarriage regularly can avoid damage, like

- Roller seizure,

- Flat spots,

- Flange wear,

- Shoe bolt loosening and cracking.

Monitor Track Tension Weekly

Like we mentioned previously, wrong tension destroys bushings, sprockets, and idlers. When working in harsh ground, you should often check how tight the tracks are. The steps include checking sag using a straight edge/string as per machine type. If tension is too tight, loosen it. If the chain is too loose, adjust immediately.

Pin & Bushing Temperature Check

In dusty or sandy areas, dry joints happen faster. So, when the machine finishes a shift, touch the end of each pin or bushing lightly. Make sure to wear gloves for safety purposes. If any joint feels hotter than 50°C, it is an indication of a dry joint.

Shoe Bolt Tightening

Loose bolts cause:

- Deformed plate

- Cracked shoes

- Elongated bolt holes (cannot be repaired)

Check tightening:

- After 50 working hours

- Every 250 hours

- Every 100 hours in heavy work

Check Alignment

Harsh sites shift the machine more, increasing misalignment, which causes wear in the excavator undercarriage parts. So, check the alignment before using the machine.

Measure Wear Properly (Monthly)

Wear measurements show exactly when to repair or replace. But they must be taken correctly. So always clean before measuring to avoid wrong readings. Measure the most worn area, not the easy spot. You should take average readings from multiple spots.

Here are a few common measurements that you should pay attention to:

- Bushing OD

- Link rail height

- Roller tread

- Grouser bar height

This helps avoid sudden failure on the job.

Smart Operating Habits to Reduce Wear

How you operate your machines can reduce wear on the excavator undercarriage parts. But even the most expert operator might overlook this. Here’s what you can do:

- Avoid high-speed travel: Tracked excavators are not exactly made for speed. When you operate them at high speed, it accelerates idler tread wear in abrasive ground.

- Reduce reverse movement: While it may not always be possible, but to avoid reversing as much as possible, as it can cause heavier bushing wear.

- Avoid continuous turning in one direction: This is essential to prevent scalloping and link wear.

- Use narrower shoes when possible: Wide shoes twist the track in rocky areas and crack links. This also increases undercarriage wear.

When Replacement Becomes Necessary, Quality Matters

Even with the best inspection routine, you can’t fully prevent wear in harsh soil, rocky mines, or wet clay conditions. Eventually, parts will reach their service limit. And when it does, you should avoid replacing it with poor quality parts. While they might come with a low upfront cost, when you consider the overall cost, they become more expensive.

Why Choose High-Quality Brands Like DOZCO?

At DOZCO, our excavator undercarriage parts stand out because:

- We use proprietary alloy compositions designed for extreme wear resistance.

- Every part is field-tested in harsh conditions before going to market.

- Our track chains, rollers, sprockets, and idlers fit all major OEM machines.

- We maintain a ready stock for quick delivery, reducing downtime.

For owners and contractors, this means fewer breakdowns, fewer stoppages, and a lower cost-per-hour.

Final Analysis

When the environment is harsh, wear and damage on the machine increase. Since the undercarriage stays in constant contact with the ground, it suffers the most. This also raises the risk of sudden breakdowns and workplace accidents. However, with frequent maintenance, it’s possible to reduce wear and extend the lifespan of the excavator undercarriage parts. That’s why it’s important to follow a proper maintenance routine. And if replacement becomes unavoidable, choose a reliable manufacturer like DOZCO. We produce undercarriage parts specially designed for tough working conditions.

FAQs

My excavator works mostly in sandy soil. How often should I clean the undercarriage?

In sandy sites, cleaning should be done daily, and sometimes twice a day if the sand is fine and sticky. Sand accelerates wear on rollers, bushings, and sprockets, so frequent cleaning prevents early damage.

We work on hilly terrain. Why are my sprockets and idlers wearing out so quickly?

Side slopes shift the load to one side, causing sprocket side wear and idler flange wear. Regular alignment checks and reducing one-direction turning can slow this down.

Is monthly wear measurement necessary?

If your excavator is working in harsh conditions, yes.

Measurement lets you predict:

- When to turn bushings

- When to change rollers

- When to replace links

How often should I check the pin and bushing temperature?

Check weekly and daily if you work in sand, dusty mines, or stone quarries. A hot joint (>50°C) means a dry joint that can fail soon.

Should I use wide track shoes for all job sites?

No. Wide shoes help in soft ground but are bad for rocky terrain, slopes, and dry abrasive sites. They increase twisting and cause link cracking. So, it is better to use the narrowest shoe that still provides traction.