How Rock Breakers Operate?

">

">

- Last Modified: 09 Feb 2026

-

Priyankar Das

When it comes to construction, mining, or demolition, breaking large rocks into manageable pieces using explosives is often not an option. Especially when you are working in urban areas or environmentally fragile regions, explosives can cause more damage. That’s where contractors prefer using rock breakers. These heavy-duty attachments, mounted on machines, including excavators and backhoe loaders, are designed to break through stone, concrete, and hard surfaces with efficiency.

But how exactly do they operate? This article explores how rock breakers operate, best practices and what to avoid:

What is a Rock Breaker?

A rock breaker is a powerful hydraulic attachment that delivers high-impact blows to break hard materials. Unlike blasting or manual hammering, rock breakers provide operators with more precision and control, which increases workplace safety. A hydraulic rock breaker can be used for both primary breaking, which involves direct rock breaking at quarries or sites, and secondary breaking to break down boulders and large chunks.

How Do Hydraulic Rock Breakers Work?

Rock breakers can be powered by electrical, hydraulic, or pneumatic systems. However, modern machines use a hydraulic mechanism for greater force and efficiency.

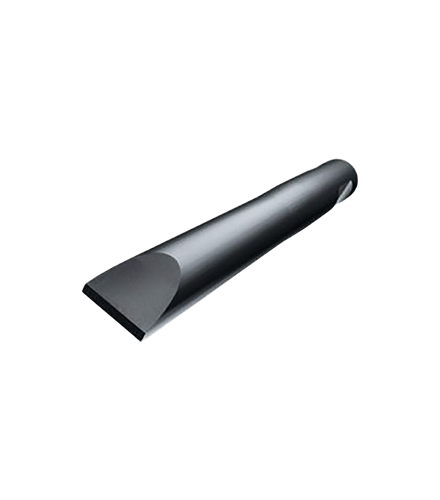

These hydraulic breakers operate by channeling pressurized hydraulic oil from the carrier machine into the breaker. This pressure drives a piston, which strikes the chisel, delivering powerful repeated blows to the rock surface.

Types of Hydraulic Rock Breakers

Hydraulic rock breakers are further classified based on their functional mechanism:

- Oil Thrust Breaker: Here, the attachment uses hydraulic oil as the primary driver of impact force.

- Gas Thrust Breaker: These types of breakers use a combination of both hydraulic oil and nitrogen gas. The main breaking force comes from the nitrogen chamber.

Gas-assisted breakers typically deliver higher impact energy and are widely used for tough applications.

Carrier Machines Compatible with DOZCO Rock Breakers

DOZCO manufactures light plus to heavy range hydraulic rock breakers. Some of the models also come with Anti-Blank Firing systems such as DOZCO D75, DOZCO D110, and DOZCO D155. The system uses a sensor to detect when the breakers are touching the surface to avoid accidental or unintended firing of a blank round. This prevents damage to the internal compounds of the rock breaker and increases its life span.

DOZCO Rock breakers are versatile attachments and can be mounted on:

- Excavators (0.5–100 ton class)

- Mini excavators

- Backhoe loaders

- Skid steer loaders

- Pedestal booms

This flexibility makes them useful across industries like construction, quarrying, mining, and demolition.

Key Principles of Rock Breaker Operation

To use a rock breaker effectively, operators need to follow specific techniques. Proper handling is essential for maximum productivity and longer equipment life.

1. Correct Angle of Operation

Always position the breaker 90° to the rock surface. Because wrong angles cause the tool to slip, create “blank blows,” and risk damaging both the breaker and carrier.

2. Advance Operation

When breaking rocks, never start breaking from the middle of a rock. Begin from the edges. This creates cracks and weakens the rock’s structure, so breaking becomes much easier. When you advance gradually, it also boosts productivity.

3. Continuous Operation Limits

You should avoid holding the breaker in one spot for more than 30 seconds. Since the blows are powerful, prolonged blows can generate excessive heat, leading to tool deformation. It is recommended to reposition the tool at regular intervals.

4. Proper Thrust Application

Operators must apply the right amount of thrust force.

- Too little means insufficient breaking power! The energy transfers to the breaker body, causing damage.

- On the other hand, if it is too much, it can cause carrier instability, piston rod stress, and violent rebound.

What NOT to Do with a Rock Breaker

When dealing with rock breakers, you need to keep in mind that there are specialized tools, and using them incorrectly can cause serious damage. As an operator, you should avoid:

- Using it as a sledgehammer.

- Continuing blows after the rock is broken.

- Dragging, pushing, or levering rocks .

- Using it for lifting or transporting material.

- Operating with the carrier’s cylinder fully extended.

- Running the breaker underwater without a special kit.

Each of these misuses increases wear, risks cracks, and reduces the machine’s lifespan.

Why Proper Operation Matters

Correct operation of a rock breaker not only improves efficiency but also:

- Reduces downtime and repair costs.

- Extends the life of the breaker and carrier.

- Ensures operator safety.

- Enhances productivity on-site.

Manufacturers like DOZCO also design breakers with advanced materials to withstand high pressure, wear, and abrasion. And features like Anti-Blank Firing, Auto Lube, and Valve Adjuster make the attachment more reliable and cost-effective in the long term when handled correctly.

Final Thoughts

Externally, rock breakers might look simple with just a chisel hammering down on stone, but their operation is a fine balance of force, angle, timing, and technique. It is not just about choosing the right breaker type for your project but also following proper operating practices for higher productivity and a longer lifecycle.

Frequently Asked Questions

Can a rock breaker be used on concrete as well as rocks?

Yes. Hydraulic breakers are effective on reinforced concrete, asphalt, and other hard surfaces in addition to natural rock.

How do I choose the right size rock breaker for my excavator?

The breaker should match your carrier’s weight class, hydraulic flow, and operating pressure. Using an undersized or oversized breaker can cause inefficiency and equipment damage.

What is Anti-Blank Firing in rock breakers?

DOZCO’s rock breakers come with a system that prevents the piston from firing when the tool is not in contact with material. This reduces wear, prevents damage, and extends the breaker’s lifespan.

How long can I operate a rock breaker continuously?

Avoid continuous operation in one spot for more than 30 seconds. This prevents overheating and tool deformation.

Are rock breakers cost-effective compared to blasting?

Yes. In urban or sensitive areas, breakers are safer, more precise, and avoid the risks associated with explosives.