When & Why Should You Replace Excavator’s Undercarriage Parts with High-Quality Ones?

">

">

- Last Modified: 09 Feb 2026

-

admin_promotedge

Heavy machinery like a dozer or an excavator works in harsh environments like mines, construction sites, and rough terrain. Hence, stability becomes a critical factor. The undercarriage part supports the machine and helps it move forward in various terrain.

While the undercarriage is manufactured with high-quality material, daily wear and tear, or lack of maintenance can impact its performance. Operators thus need to replace undercarriage parts on a regular basis. However, there are several options available in the market, which can create confusion.

This article explore when you should replace undercarriage parts why it is essential to choose high-quality ones:

When to Replace Undercarriage Parts

Well-maintained undercarriage parts improve operational safety and efficiency. However, it is essential to know when to replace them. Here’s when you should consider replacing:

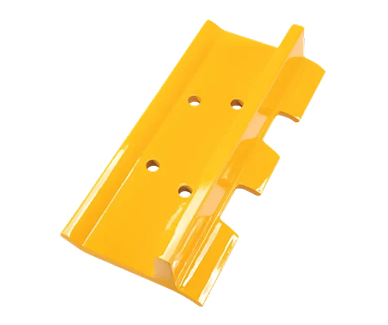

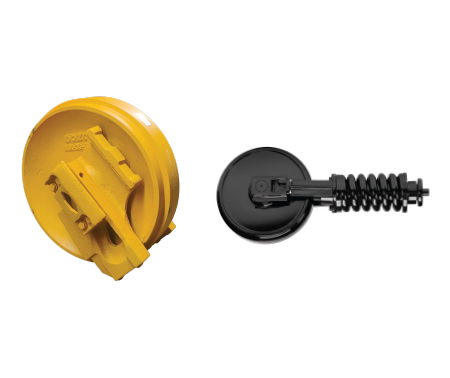

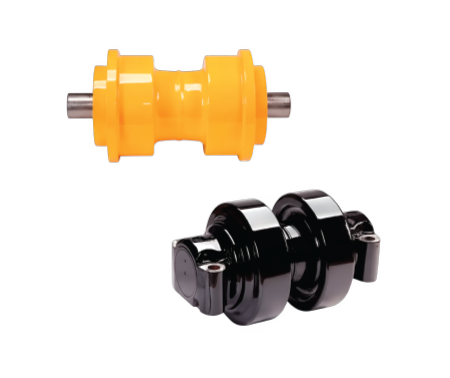

- If rollers, idlers, sprockets, or track links show wear beyond manufacturer specs.

- If you’re constantly tightening the worn-out track, your pins, bushings, or track links.

- If track shoes are damaged, they can compromise grip, balance, and overall machine stability.

- If there is any clicking, grinding, or uneven rumbling sounds, as it indicates misalignment or failing undercarriage components.

The Advantages of Quality Undercarriage Parts

Replacing undercarriage parts for heavy equipment can be expensive. However, operators should always choose high-quality parts from reliable manufacturers, rather than the low-quality parts available in the market.

Here are a few perks of choosing high-quality parts, like sprockets, track shoes, track link assemblies, idlers and rollers:

Elongates the Lifespan of the system

Manufacturers like DOZCO manufacture high quality parts for undercarriages. These components fit perfectly on machines manufactured by various OEMs like Caterpillar or Komatasu. Hence, the parts function smoothly which improve the lifespan of the system.

Reduces Downtime Significantly

Sudden breakdowns can impact your project pace. Low-quality attachments can cause high stress or wear, which can lead to machine failure. Quality parts on the other hand are more durable, and less prone to wear and tear which minimizes unexpected downtime and repair costs.

Improves Operational Performance

Quality components maintain optimal machine performance, leading to higher productivity and fuel efficiency. This translates to more work completed in less time and lower operating costs.

Provides better Fuel Efficiency

Worn undercarriage components increase rolling resistance, leading to higher fuel consumption. Quality parts help maintain optimal rolling resistance, reducing fuel costs.

Lower Total Cost of Ownership

While the initial investment in quality parts may be higher, the extended lifespan, reduced downtime, and improved performance often result in a lower total cost of ownership over the life of the machine.

Cost Analysis: Quality vs. Low-Cost Parts

They say “buy cheap, buy twice.” It accurately describes why you should never buy a low-quality dozer or excavator undercarriage parts at a cheaper price. When you are purchasing a product, you can’t just consider the initial, you have to consider the overall expense.

Here’s a detailed analysis, on the critical factors that influences the overall price:

| Cost Factor | Low-Cost Parts | High-Quality Parts |

|---|---|---|

| Initial Cost | Lower upfront cost | Higher upfront cost |

| Installation Costs | May require frequent replacements, which might increase total labor cost | Fewer replacements needed, which means lower long-term labor cost |

| Downtime Costs | Higher due to more frequent breakdowns | Lower due to better durability and reliability |

| Repair Costs | Higher risk of failure which can increase repair costs | Lower failure rate, therefore low repair costs |

| Fuel Consumption | May increase due to inefficient operation | Offers better efficiency with optimized fuel consumption |

| Lifespan | Shorter lifespan, thus needs frequent replacement | Longer lifespan, which extends service life |

By considering all these factors, you can calculate the cost per operating hour for both quality and low-cost parts. The goal is to minimize this cost.

Let’ take two scenarios, to elaborate it in detail:

Scenario 1:

You have purchased quality parts.

- Initial Cost: $10,000

- Lifespan: 5,000 hours

- Downtime: Minimal

- Fuel Efficiency: High

Now, Cost per hour = (Initial Cost + Downtime Costs) / Lifespan

= $10,000 / 5,000 hours = $2.00/hour

Scenario 2: Low-Cost Parts

You have purchased cheap undercarriage parts:

Now,

- Initial Cost: $6,000

- Lifespan: 3,000 hours

- Downtime: 200 hours (unscheduled maintenance)

- Downtime cost: 200× $100/hour = $20,000

- Fuel Efficiency: Lower

Cost per hour = (Initial Cost + Downtime Costs) / Lifespan

= ($6,000 + $20,000) / 3,000 hours = $8.67/hour

As we can see, the cost per hour for low-quality parts is 4X higher than high quality parts.

Final Analysis

While replacing excavator and dozer undercarriage parts is something operators or contractors can’t ignore, the components they choose can impact the machine’s performance. If we consider cost-per hour, high-quality parts are more reliable and suitable. While the initial investment may be higher, operators can avoid sudden breakdowns that impact your project pace greatly. Moreover, it improves the machine’s performance, offers better fuel efficiency and lasts longer than the cheap ones. Hence, it is recommended to do a thorough cost analysis before choosing

FAQs

Q.1. Why are undercarriage parts critical for excavator performance?

The undercarriage bears the weight and movement of your machine. It provides stability and traction on various terrains. Worn or poor-quality components can lead to performance issues, downtime, and higher fuel consumption.

Q.2. What are the benefits of using high-quality undercarriage parts?

High-quality parts increase equipment lifespan, reduce unexpected breakdowns, improve operational performance, and enhance fuel efficiency—ultimately lowering the total cost of ownership.

Q.3. Isn’t it cheaper to buy low-cost parts for my excavator?

While the initial cost of low-cost parts is lower, they typically have a shorter lifespan and lead to more frequent replacements, repairs, and downtime. When you calculate cost-per-hour, high-quality parts are more economical over time.