Which Rock Breaker Should You Choose for Your Machine?

">

">

- Last Modified: 09 Feb 2026

-

admin_promotedge

When you’re in the market for a rock breaker, one question comes up again and again—”Which model is right for my machine?”

In the current construction and mining sector, hydraulic rock breakers are now a necessary tool for a vast array of applications ranging from trenching and road construction to quarrying and heavy mining. However, one of the most prevalent problems that equipment owners and site managers face is the selection of the appropriate rock breaker that fits both their machine and working conditions.

At DOZCO, we manufacture a range of high-performance, CE-certified rock breakers designed to match various carrier sizes and working conditions. This brief will help you understand how to select the right rock breaker model based on your machine size, hydraulic capacity, and operational needs.

What Exactly is a Rock Breaker?

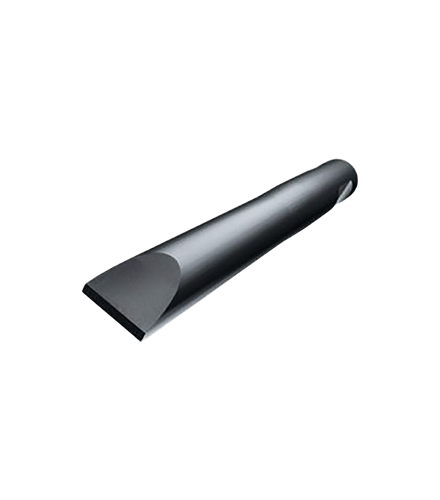

A rock breaker, also called a hammer, is an attachment that is used on excavators, backhoe loaders, and other heavy machinery. These attachments help break hard materials like stone, reinforced concrete, or asphalt.

It operates by converting the hydraulic pressure supplied by the carrier machine into high-frequency impact energy, which is delivered through a steel chisel or moil point.

What Should You Consider Before Choosing a Rock Breaker?

Let’s get into the real-world factors that matter when selecting a rock breaker model.

1. The Size of the Machine

This is your starting point. DOZCO rock breakers are designed to match certain carrier weight classes. If you equip an oversized breaker on a small excavator or vice versa, this can lead to inefficient performance or mechanical issues. Therefore it is important to identify some basic things before you make an investment decision.

- Light Range: This range consists of small backhoes, mini excavators, and skid steer loaders that have a capacity of 5 – 9 tons.

- Medium Range: This range consists of standard medium-sized excavators that have a capacity of 10 – 26 tons.

- Heavy Range: This range consists of heavy-duty excavators that have a capacity of 30 – 100 tons.

2. Hydraulic Compatibility

Every breaker requires a specific range of hydraulic oil flow (measured in litres per minute or LPM) and operating pressure (measured in bar). Make sure that your excavator meets the hydraulic specifications that the breaker needs. An undersupplied breaker won’t perform properly, while an oversupplied one may overheat or fail prematurely.

Always check your carrier’s specs rather than making random guesses. Compatibility is the key to longevity and consistent performance.

3. Nature of the Job Site

Before you make a choice, first ask yourself what you will be breaking? Soft concrete? Asphalt? Granite? Boulder?

- For light-duty tasks like curb cutting or shallow trenching, a compact breaker will do.

- For mid-level jobs like foundation removal or tunneling, a medium model is ideal.

- For heavy work such as mining or quarrying, you need a high-impact, and powerful heavy-duty breaker.

4. Impact Energy and BPM (Blows Per Minute)

Impact force and blow frequency are the major determinants behind your site productivity and equipment performance. While hard rocks require high impact power, that is, low BPM achieved from a bigger piston, soft to medium materials need higher BPM to break.

DOZCO rock breakers are equipped with adjustable BPM valves to optimize performance on different terrains.

Did You Know About the Anti-Blank Firing (ABF) System?

It is an essential safety feature that comes in-built in modern rock breakers, including most DOZCO models. This system prevents the piston from striking when there’s no load, that is, when the chisel or tool is not in contact with any material.

Operating the breaker without load (“blank firing”) can cause internal damage, increase wear, and shorten the life of the tool. In other words, ABF protects your equipment by minimizing unnecessary vibrations and makes sure each impact is applied effectively to the target material.

Which Model Will Fit Your Work the Best?

When it comes to choosing a rock breaker, we like to keep things simple and focused on real-world needs. That’s why we’ve categorized our most trusted DOZCO models into three straightforward options, based on the size of your carrier and the kind of work you do.

The Light Range

Are you working in an urban set up or does your work deal with trenching along city roads or removing old pavements? For instance, if your excavator falls in the 4 to 8-ton range, then DOZCO D75 can be your go-to choice.

Its compact design is engineered for strength, and it gives you the freedom to work in restricted spaces without compromising on impact power. Here are some features that you’ll like about this rock breaker attachment.

- Operating Weight: 426 kg

- Tool Diameter: 75mm

- Optimal Oil Flow: 50 – 90 lpm

- Impact Rate: 400 – 800 bpm

The Medium Range

Does your daily work deal in handling reinforced concrete or demolishing in congested areas? It’s time to get a breaker that delivers almost an equivalent strength as your 20-ton excavator.

For example, DOZCO D135 can be ideal for such machinery. Designed for machines in the 18 to 26-ton class, this model brings power, stability, and precision to the table. Here are some specs that make it the best pick for you.

- Operating Weight: 1725 kg

- Tool Diameter: 135mm

- Optimal Oil Flow: 120 – 180 lpm

- Impact Rate: 350 – 500 bpm

You can be rest assured as our range of mid-sized breakers can take up any challenge on a civil site.

The Heavy Range

Imagine, you are in a quarry, facing those massive granite boulders. Your 35-ton excavator is ready, but you need a breaker that can actually cut it through. This is where you need a heavy-duty rock breaker like DOZCO D155. This breaker is built for raw power. It comes with anti blank firing and anti lube features; and can break granite, basalt, and oversized blocks smoothly.

You should prefer this rock breaker because of its:

- Operating Weight: 2550 Kg

- Optimal Oil Flow: 180 – 240 lpm

- Tool Diameter: 155 mm

- Impact Rate: 300 – 450 bpm

Final Thoughts

At DOZCO, we build our rock breakers based on real-world conditions like hard soil, dense rock, long operating hours, and unpredictable challenges. When you choose a DOZCO rock breaker, you’re not just buying a tool, you’re getting a partner you can count on day in and day out.

With local manufacturing and service teams across the country, we make sure you receive the right support wherever needed in every step of the way.

Request a personalized consultation or get a quote today.