Buying Guide for Quality Undercarriage Parts

">

">

- Last Modified: 09 Feb 2026

-

admin_promotedge

Undercarriages are widely used for heavy machinery like dozer and hydraulic excavators. It adds stability to the machine which is much needed when working in rugged terrain observed in mines, construction sites, and agricultural fields. Undercarriages are made of different parts, each of which plays an important role.

However, the undercarriage parts can degrade over time or due to a poor maintenance schedule. This can impact your operational productivity and even cause workplace accidents. Therefore, it is essential that you choose high-quality excavator and dozer undercarriage parts.

But the question often arises amongst contractors and operators: how do you choose Caterpillar undercarriage parts, Hitachi undercarriage parts, or Kobelco undercarriage parts? Do you purchase undercarriage parts directly from machine OEMs like Kobelco or Caterpillar, or from a specialized component OEM like DOZCO? This article shares insights on the factors you need to consider when purchasing excavator or dozer undercarriage parts:

Why Quality Undercarriage Parts Are so Important in Heavy Machinery?

Did you know that undercarriage parts can account for 40–50% of total machine maintenance costs over a lifetime? This says a lot about why you need to choose high-quality undercarriage.

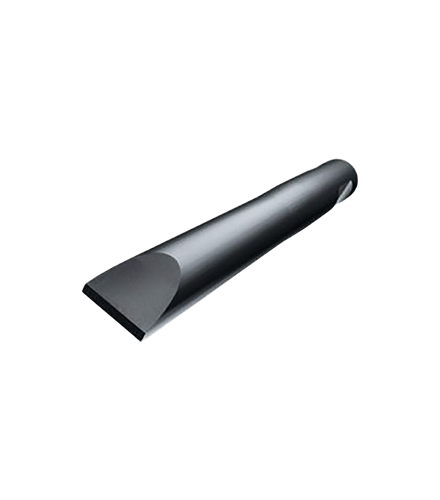

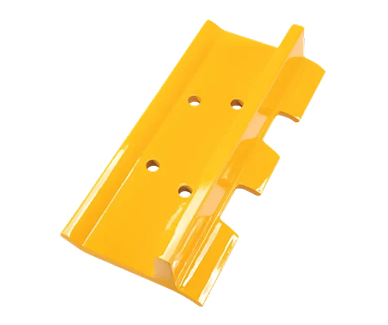

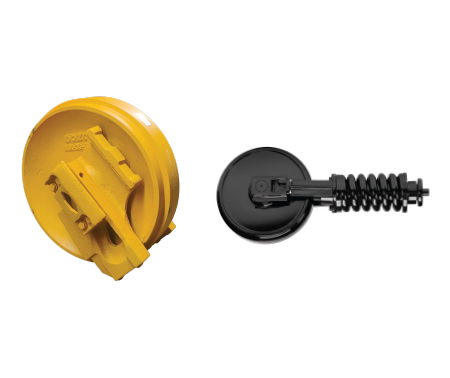

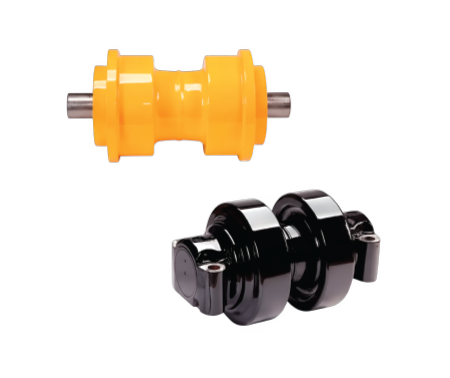

An undercarriage is made of different parts, such as rollers, idlers, track link assembly, sprockets, track guards, and track shoes. These components are constantly exposed to abrasive soils, rocky terrains, and uneven loads. When you use poor-quality parts, they don’t just wear out faster and create a chain reaction of problems:

- Shorter service life and more frequent replacements

- Increased downtime that disrupts project schedules

- Reduced fuel efficiency due to poor fitment and alignment

- Higher long-term operating costs

So, it becomes very important that you use high-quality excavator and dozer undercarriage parts.

Read more on: When & Why Should You Replace Excavator’s Undercarriage Parts With High-Quality Ones?

Key Factors to Consider When Buying Undercarriage Parts

When you go buy Caterpillar undercarriage parts or Hitachi undercarriage parts, there are several factors you need to consider, such as:

a) Compatibility & Fitment

When you are replacing an excavator or dozer undercarriage parts, it is important that they meet OEM specifications. The parts need to fit the undercarriage properly for

- Smoother operation,

- Better fuel efficiency, and

- Longer service life.

If the sprocket tooth is not aligned with a bushing or a track shoe that’s too wide for the frame, it can cause chain derailment or uneven wear. DOZCO’s dozer undercarriage parts are manufactured to meet world class OEM standards and fit perfectly amongst different brands, including Caterpillar, Hitachi, and Kobelco.

b) Material & Build Quality

The undercarriage carries the entire load of the machine. Thus, reliable manufacturers use high-quality steel and advanced technology while manufacturing dozer undercarriage parts. Since the machine is often in a harsh environment, the undercarriage parts need to be durable and built differently for different demands. For instance,

-

- Track Chains range from unsealed chains (suited for light use) to sealed chains, and advanced sealed and lubricated (SALT) systems. These are specially designed to reduce friction. For heavy-duty jobs, floating bushing chains and IPR (ITM Pin Retainer) systems offer longer service life.

- Some machines use a diagonal brace undercarriage, while others use a pivot shaft design. So, you need to consider the structure of the machine before deciding undercarriage parts.

c) Application & Working Conditions

Where you are working matters a lot when you choose undercarriage parts for your dozer or excavator. Not all undercarriage parts are designed for the same environments. Here’s a look at which parts work best in which field:

- Rocky terrains need reinforced shoes and sealed & lubricated chains (SALT).

- For sand & soft soils, go for track shoes with wider floatation.

- Specialized designs, such as floating bushing SALT chains or IPR systems, extend pin and bushing life by 50–60% compared to conventional sealed chains.

d) Cost vs. Lifecycle Value

Many contractors get tempted by the lowest upfront price of poor quality dozer undercarriage parts. But you need to consider the cost per hour of operation. A high quality chain or roller can last 20% longer, which will reduce not just replacement costs, but also downtime losses. The real savings come from longer service life and a reliable warranty, not just initial discounts.

e) Supplier Reliability & Warranty

Whether OEM or niche, a supplier’s support network matters. Do they offer a warranty for their parts with warranty? Do they ensure availability and timely delivery? This can be the difference between days of downtime and machines back in the field. You should also consider their reputation and expertise. They should be open to after-sales service and be prompt with it in case of emergencies.

Why Should You Choose a Component Manufacturer Like DOZCO?

Since undercarriage parts of a dozer or excavator play a major role in efficiency and safety, it is better to choose either machine OEMs like Caterpillar, Komatsu, or Kobelco, or a specialized undercarriage part manufacturer like DOZCO.

Here are a few reasons why you should consider choosing a DOZCO:

- Decades of Expertise in UndercarriageWith over 43 years of experience, we have a deep specialization in designing and manufacturing undercarriage systems. We primarily focus on perfecting undercarriage parts that meet diverse working conditions.

- Comprehensive Product RangeDOZCO manufactures a wide range of products from sprockets to track link assemblies. All the products are made of high-quality materials to withstand harsh conditions and have a longer lifespan.

- Better AccessibilityDowntime can cost contractors heavily. At DOZCO, we address this with strategic stock availability, ensuring ready-to-ship parts and minimum downtime for customers.

- Local SupportDOZCO is extended across 25+ countries worldwide. We also provide ground-level training and technical support for customers. Our field teams conduct on-site training, so contractors don’t just buy parts but also know how to maximize their lifespan.

- Innovation and Quality CommitmentBacked by in-house R&D and manufacturing, DOZCO emphasizes quality and innovation in every undercarriage component. Our products are ISO 9001:2015 certified.

The Bottom Line

When you purchase excavator or dozer undercarriage parts, you need to consider their long-term efficiency. High-quality parts are expensive, but they need low maintenance and less frequent replacement. Consider whether the parts are suitable for your machine, made of high-quality materials, and durable before making a decision.

FAQs

Q1. Why are quality undercarriage parts so important in heavy machinery?

Undercarriage systems make up nearly 40–50% of a machine’s lifetime maintenance cost. Components like rollers, idlers, track link assemblies, sprockets, and track shoes constantly face abrasion, uneven loads, and tough ground conditions. Poor-quality parts wear out quickly, leading to more downtime, higher fuel consumption, and safety risks. That’s why investing in high-quality undercarriage parts saves money in the long run.

Q.2. Why should I choose DOZCO for dozer and excavator undercarriage parts?

DOZCO combines the reliability of an OEM with the flexibility of a component specialist:

- 43+ years of expertise in undercarriage manufacturing

- Full product range

- Strategic stock availability

- Global reach (25+ countries)

- local training & technical support

- ISO-certified, in-house R&D

Q.3. Are DOZCO parts compatible with Caterpillar, Hitachi, and Kobelco machines?

Yes. DOZCO undercarriage parts are designed to meet world-class OEM standards and are compatible across major machine brands, including Caterpillar, Hitachi, Komatsu, and Kobelco. This ensures smooth fitment, durability, and performance across equipment fleets.

Q.4. Do DOZCO parts come with a warranty and after-sales support?

Absolutely. DOZCO provides warranty coverage, reliable after-sales support, and even on-site field training to help contractors extend the life of their undercarriage parts.